R-SPL-C SafetyPlus - Countersunk

High performance mechanical anchor - countersunk version

Features and benefits

- High performance in non-cracked concrete confirmed by ETA Option 7

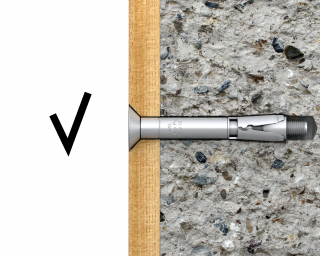

- Design of SafetyPlus allows for easy through fixing

- Integral controlled collapse and anti-rotation feature ensures fixture is firmly secured

- Unique zig-zag feature provides balanced expansion, ensuring secure setting and maximised load-bearing capacity

- Case-hardened nut with optimum taper angle for enhanced expansion

- Fire resistant

Product information

Size |

Product Code |

Anchor |

Fixture |

|||

Thread size |

External diameter |

Length |

Max. thickness |

Hole diameter |

||

d |

dnom |

L |

tfix |

df |

||

[mm] |

[mm] |

[mm] |

[mm] |

[mm] |

||

M8 |

R-SPL-C-08090/20 |

8 |

12 |

90 |

20 |

14 |

M10 |

R-SPL-C-10105/25 |

10 |

15 |

105 |

25 |

17 |

M12 |

R-SPL-C-12125/30 |

12 |

18 |

125 |

30 |

20 |

M16 |

R-SPL-C-16145/30 |

16 |

24 |

145 |

30 |

26 |

Base material

-

Non-cracked concrete C20/25-C50/60

-

Unreinforced concrete

-

Reinforced concrete

For use also with

-

Natural Stone (after site testing)

Applications

- Structural steel

- Masonry support

- Cladding restraint

- Road Signs

- Heavy machinery

- Racking systems

- Industrial doors

- Safety barriers

Installation guide

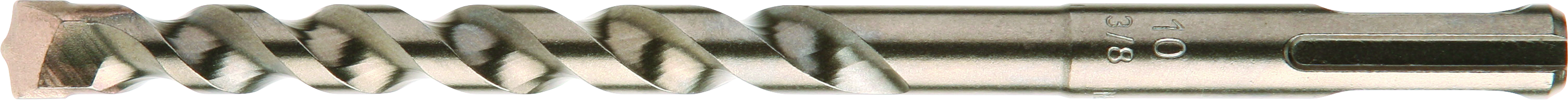

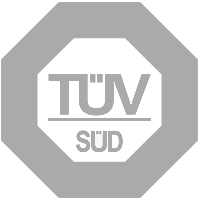

- Drill a hole of required diameter and depth

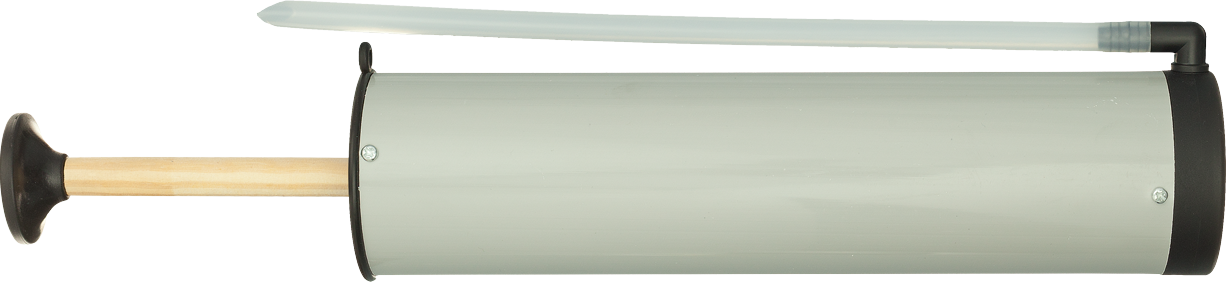

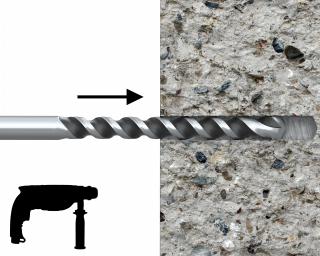

- Clear the hole of drilling dust and debris (using blowpump or equivalent method)

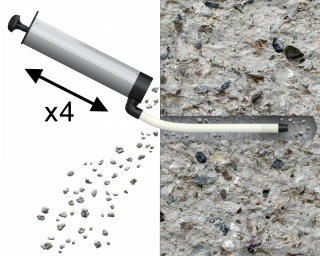

- Insert anchor through fixture into hole and tap until required installation depth is achieved

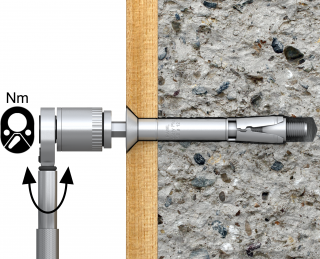

- Tighten to the recommended torque

Installation data

Size |

M8 |

M10 |

M12 |

M16 |

||

Thread diameter |

d |

[mm] |

8 |

10 |

12 |

16 |

Hole diameter in substrate |

d0 |

[mm] |

12 |

15 |

18 |

24 |

Installation torque |

Tinst |

[Nm] |

25 |

50 |

80 |

180 |

Wrench size |

[English]: Hex |

[mm] |

6 |

8 |

10 |

12 |

Min. hole depth in substrate |

h0 |

[mm] |

85 |

95 |

105 |

130 |

Min. installation depth |

hnom |

[mm] |

70 |

80 |

90 |

110 |

Min. substrate thickness |

hmin |

[mm] |

100 |

105 |

120 |

150 |

Min. spacing |

smin |

[mm] |

60 |

70 |

80 |

100 |

Min. edge distance |

cmin |

[mm] |

90 |

105 |

120 |

150 |